Have you found yourself Googling well pump repair near me? Understanding how well pump systems work, you will have good knowledge of water wells and well pump repairs.

Property owners will experience well pump problems. Well pumps are essential for providing water to your home; periodic well pump repairs or well pump replacements will be required. When well pumps malfunction, they can cause considerable disruption to daily life if not attended to promptly.

This comprehensive article on well pump repair includes well pump replacement and the cost of well pump services.

Understanding the basics of water well pump repair services is crucial for getting your water sy

What Can Cause a Well Pump Problem?

- Electrical Issues

- Low Water Level

- Clogged or Damaged Components

- Worn or Damaged Pump Components

- Incorrect Well Pump Sizing or Installation

- Waterlogged Pressure Tank

- Leaks in the System

- Insufficient Power Supply

- Frozen or Blocked Pipes

- Corrosion or Rust

A well pump repair professional can diagnose and fix pump problems. Informed decisions regarding water system maintenance can save time, money, and water disruptions… especially on weekends and holidays!

Comparing Well Pump Repair Costs: Local Well Pump Contractors

Comparing well pump repair contractor costs is crucial to ensuring you receive the best service without breaking the bank. 💧 Thoroughly researching and analyzing different contractors’ offers will help you find the ideal balance between affordability and quality, 🏡✨ultimately catering to your specific budget and needs.

How to Hire a Well Pump Repair Service

To hire a well pump repair service, here’s what you should consider when looking for a reliable and experienced contractor.

Experience and Expertise

Look for a water services contractor with experience and expertise in well pump repair. Consider their experience in the industry and whether they specialize in the type of water well service you need.

Licensing and Insurance

Check if the contractor is licensed and insured. A valid license ensures they have met the necessary qualifications. Insurance protects you from any potential liability during the repair process.

Reviews and Recommendations

Read online reviews and ask for recommendations from friends and neighbors. Reviews on water well contractor websites like Water Well Worx can provide valuable insight into a contractor’s reputation.

Create a Shortlist of Potential Well Pump Contractors

After researching and considering the abovementioned factors, create a shortlist of potential well pump contractors. This will allow you to compare and contrast their strengths and weaknesses more easily.

Compare Costs Between Well Pump Repair Contractors

Contact your shortlisted contractors and request estimates for the well pump repair service. Remember that the average cost to repair a well pump ranges from $330 to $1,500. Compare a few well pump repair cost quotes choosing a contractor that fits your budget but also meets your requirements.

What is the Average Well Pump Repair Cost?

When repairing your well pump, costs vary depending on the issue and the parts needed. On average, well pump repair costs a few hundred to a few thousand dollars. It’ll depend on the scope of your water well pump.

Most Common Well Pump Repairs Include:

- Replacing a Worn or Damaged Impeller: The impeller is a crucial pump component; it moves water through the pump. Over time, the pump impeller can become worn or damaged, reducing efficiency and potentially causing the pump to malfunction.

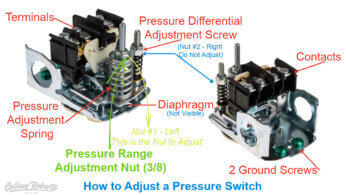

- Fixing a Broken Pressure Switch: The pressure switch regulates the pressure in the water system. If a pressure switch fails, the pump may not turn on or off as it should. Pressure switch failure can lead to water pressure issues or the constant running of the pump.

- Repairing or Replacing a Faulty Motor: The well pump’s motor powers the entire system. If it becomes damaged or fails, the pump will not function properly. A repair or well pump replacement may be necessary.

- Resolving Electrical Issues: Electrical problems, such as short circuits, blown fuses, or damaged wiring, can cause pump malfunction. Repair these issues to restore the well pump’s normal function.

- Fixing Leaks in the System: Leaks in the water pumping components or plumbing connections can reduce water pressure. Identifying and repairing these leaks is essential for maintaining the pump’s performance. Leaks may also cause the pump to cycle off and on repetitively.

- Replacing a Worn or Damaged Check Valve: Check valves ensure that water only flows in one direction through the system. Water may flow back into the well if damaged, leading to well pump cycling and reduced efficiency.

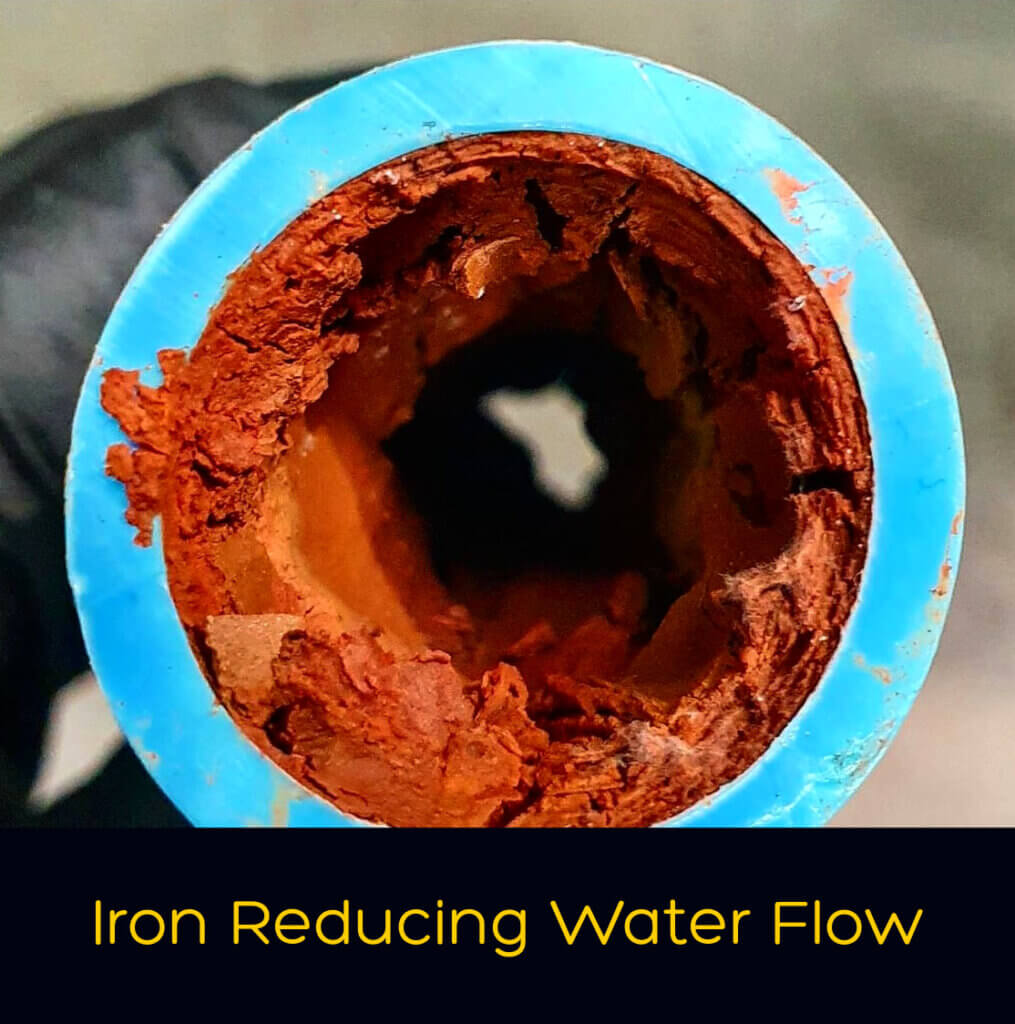

- Cleaning or Replacing a Clogged Filter Screen: The filter screen prevents debris from entering the well pump system. Over time, it can become clogged and reduce water flow, necessitating cleaning or replacement. It could be the well pump or the screen installed in the water well.

- Adjusting or Replacing a Malfunctioning Pressure Tank: A failing pressure tank can cause inconsistencies in water pressure. Pressure tank problems lead to more severe issues if left unaddressed. Identify the source of the problem, a ruptured bladder, faulty pressure switch, or a well that may be running dry.

Sometimes, simple adjustments, like calibrating the pressure switch or recharging the air pressure, may be enough. However, the pressure tank or its components are beyond repair; replace it.

How to Find a Good Local Well Pump Company

Request an Online Estimate

Request a few well pump repair or replacement estimates from local pump repair companies. It’s essential to understand the specific repair costs you may face. Search online; pump service professionals are often small owner-operators and may not have a big online presence. If you can find a small local well pump repair business, they typically have great experience and provide better estimates.

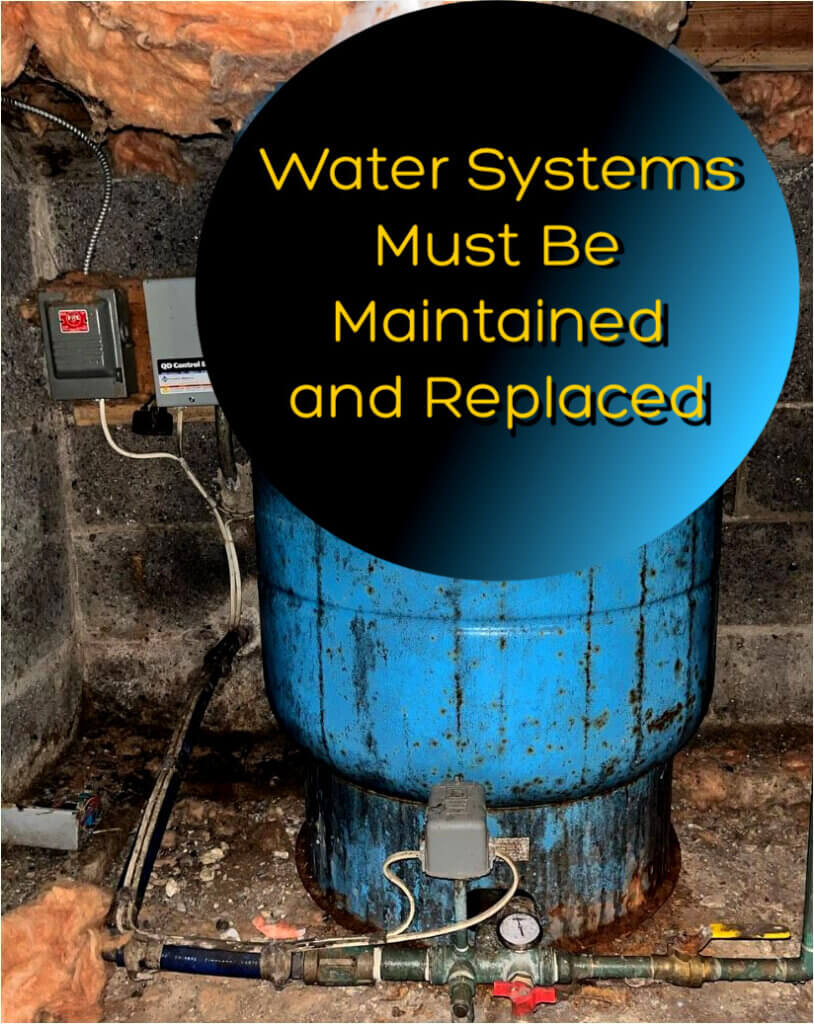

Also, remember that regular water well and well pump system maintenance can help you avoid costly repairs in the long run! Unfortunately, it’s so common for water systems to need more care.

Complete Well Pump Replacement Cost

What is the cost for a complete replacement of a well pump? Several factors determine the cost to replace a submersible well pump. The depth of the well, size, type of pump, materials, location, and whether you hire a professional or DIY. Here’s a general overview of a submersible well pump replacement cost.

What Does it Cost to Replace a Well Pump?

- Well Pump Replacement Cost: Basic submersible pumps cost a few hundred dollars for a basic pump. High-capacity well pumps can cost several thousand dollars or more. The well pump replacement cost will depend on horsepower, flow rate, well depth, and materials used. Invest in a good quality pump, as the labor is costly to pull the pumps and reinstall them.

- Well Pump Replacement Labor Cost: Labor costs can range from several hundred to a couple of thousand dollars. Depending on the job’s complexity and local labor rates for well pump replacement services. Getting quotes from multiple contractors is essential to get the best price.

- Additional Installation Materials: With a pump, other materials, such as piping, wiring, or fittings, will be added to the invoice.

- Miscellaneous Well Pump Installation Costs: Additional costs may include permits, water testing, or well rehabilitation. If the well has not been maintained, it often increases the costs to repair. To replace a well pump equipment a crane truck or pump hoist may be used to pull the old pump.

Considering the Well Pump Cost Factors

Replacing a well pump in a shallow drilled well could cost as little as $1200.00. But typically, a complete well pump replacement will cost considerably more. It’s best to get two of three well pump cost estimates.

Connect with a Local Well Pump Replacement Expert

Comparing well pump repair costs to ensure you receive the best service without breaking the bank. 💧 A few estimates will help you find the ideal balance between affordability and quality, 🏡✨ to fit your budget and well pump repair needs.

To save money on the cost of a well pump replacement, consider doing the job yourself if you have the necessary skills and tools. However, hiring a professional for safety and quality assurance is often best, especially if you’re unfamiliar with well pump installations.

The replacement cost for a submersible pump will vary and depend on many factors, including the type of pump, the depth of the well, local labor rate, and additional work that may be required, such as replacing wiring or pipes and maybe the pressure system, etc.

What Are the Signs That a Well Pump is Failing?

Several signs may indicate that your well pump could be failing or experiencing problems. Awareness of the signs of well pump problems can help you identify the issue early and promptly call for pump repair service if required.

“Keeping an eye out for signs of well pump problems can help you identify and address well pump issues before causing major disruptions or damage to your water supply system.”

— Water Well Worx

Identifying Well Pump Problems

Sudden Loss of Water Pressure in the House

There could be several reasons for a loss of water pressure in the house on a well water system. Some of the most common causes include:

- Clogged Filters or Pipes: Sediment, debris, or mineral buildup in filters, lines, or fixtures can restrict water flow and lead to a drop in water pressure.

- Pressure Tank Issues: It is possible that the pressure tank needs to be replaced or correctly set, resulting in low water pressure. A waterlogged or ruptured pressure bladder in the tank can also contribute to the loss of water pressure.

- Well Pump Problems: The water well pump could malfunction. A malfunctioning well pump could be due to worn-out parts, a damaged impeller, or electrical issues.

- Leaks: A well water system could be leaking due to several reasons. Leaks can occur at various points within the system, including the well’s casing, wellhead, plumbing connections, pressure tank, or distribution system. The system could also leak at the pump, requiring a well pump repair.

- Valve Issues: A partially closed or malfunctioning valve in the system can restrict water flow, leading to reduced water pressure.

- Well Issues: If your well is not producing enough water or has experienced a drop in the water table, it may result in low water pressure. In this case, you may not need a well pump repair service yet, but you may need some advice on repairing a well if running out of water.

It’s usually best to consult a water well professional specializing in well pump repairs or repairing a well to diagnose and resolve the concern. They can help determine the cause of the problem and recommend appropriate solutions to restore your water pressure.

Noisy Well Pump Operation

Your well pump should operate relatively quietly. However, you may hear unusual or loud noises from the pump or pressure system. In that case, it may signal mechanical problems or damaged parts. To address this issue, have your well pump checked by a qualified pump tech who can identify the cause of the noise and repair the well pump if needed.

Well Pump Repair If an Inconsistent Water Supply

When you notice fluctuations in your water supply, such as intermittent water flow or inconsistent water pressure, it may indicate issues with your well pump or other water system components.

In such cases, it’s essential to identify the root of the problem and have it fixed by a professional to prevent further complications. For example, it could be a well pump repair, or you may be repairing a well if it’s beginning to run dry. Either way, it could be urgent and may cause damage to your well pump or well.

Well Pump Problems and High Energy Costs

Pump problems and high energy bills are often related. Pump issues can increase energy consumption and cause higher energy bills.

Well Pump Problems and High Energy Bills:

- Inefficient or Old Pump: Older pumps or those not energy-efficient may consume more energy than necessary, leading to higher energy bills. Rather than a water well pump repair, replacing the well pump with a more energy-efficient pump can help reduce energy consumption and lower energy costs.

- Pump Cycling: If your well pump is frequently clicking off and on, it could be a sign of a problem with the pressure tank, pressure switch, or a leak in the system. Constant cycling of a well pump can cause the pump to work harder and use more energy, increasing your energy bill and creating a costly well pump repair.

- Leaks in the System: Leaks in your water system can cause your pump to work harder to maintain pressure, increasing energy consumption. Identifying and fixing leaks in the water system can help reduce energy usage and lower your energy bills.

- Incorrect Water Pump Size: A water well pump that’s too small for your water demand will work harder and longer to supply the required water, leading to higher energy consumption. Similarly, a too-large well pump will also consume more energy than necessary. Ensuring you have the correct pump size for your needs can help reduce energy usage.

- Poorly Maintained Pump: Well pumps need to be well-maintained, or they become worn-out and can become inefficient, using more energy than necessary to function. Regular maintenance and inspections can help identify problems reducing the need for well pump repairs, leading to more efficient water pumping operation and lower energy bills.

A water pumping system should be regularly inspected and maintained to reduce high energy bills related to well pump problems. It involves checking for leaks, monitoring pump cycling, and ensuring the water well pump is the right size for the well and demand.

“Upgrading to an energy-efficient pump and fixing any issues can reduce energy consumption and pump repair costs.”

— Water Well Worx

What are the Different Types of Well Pumps?

The following section discusses the types of pumps most commonly encountered during a well pump repair service. Understanding the features and functions of these types of well water pumps will help you determine the type that best suits your property.

Reliable: Submersible Well Pumps are Durable

Pumps designed for submersion in water are known as submersible pumps. In addition to domestic water supply, irrigation, and industrial water extraction, they serve various purposes.

Submersible Well Pumps Have the Following Advantages:

- Efficient Operation: Submersible pumps are submerged, so they do not require additional energy to lift water, resulting in greater efficiency. They can also handle high water pressure and pump water from deeper sources.

- Quiet Operation: As submersible pumps are submerged, they operate with significantly less noise compared to above-ground pumps. Making submersible pumps ideal for residential and noise-sensitive applications.

- Longer Lifespan: Modern-day submersible pumps are made from corrosion-resistant materials such as stainless steel. The water surrounding the pump also provides cooling, reducing the chances of overheating and extending the pump’s life.

- Less Maintenance: With fewer exposed components and a sealed design, submersible pumps are less prone to damage and require less maintenance than above-ground pumps resulting in fewer well pump repairs.

- Reduced Risk of Cavitation: Cavitation can occur when a pump is not fully submerged, causing damage to the impellers and reducing efficiency. Fortunately, pump cavitation instances are rare for submersible pumps – regardless of whether they are hydraulic or electric.

- Compact Design: Submersible pumps have a smaller footprint, making them suitable for tight spaces and installations with limited space.

- No Priming Required: Unlike above-ground pumps, submersible pumps do not require priming because they are always submerged. As a result, there is no need for manual priming, and the pump will never lose its prime.

- Better Water Quality: Submersible pumps reduce the risk of water contamination. They are installed below the water level and therefore are less likely to draw in contaminants from the surface.

Overall, submersible water well pumps offer several advantages: efficiency, durability, low maintenance requirements, and fewer well pump repairs. These features make them attractive for various water extraction applications, including constant pressure systems, which have become very common on rural properties!

What is the Average Life Expectancy of a Submersible Well Pump?

The average lifespan of a submersible well pump varies depending on factors such as the pump’s quality, the well’s conditions, and maintenance practices. Generally, a high-quality submersible well pump lasts 10 to 15 years. However, in some cases, they may even last up to 25 years with proper care and maintenance.

Environmental factors, such as corrosive elements in the water or extreme temperature fluctuations, can impact the pump’s longevity. Regular maintenance and inspection, including checking for any signs of wear or corrosion, will help ensure a longer lifespan for the pump. Ultimately, investing in a well-built pump and maintaining it properly will provide a better chance for extended service life.

Jet Pumps: Shallow Well Systems

Jet and shallow well jet pumps are popular water supply systems because of their efficiency and reliability. The deep well jet pump is designed to supply water from deeper wells.

Some Key Advantages of Jet Pumps Include the Following:

- Versatility: Jet pumps can be used for various applications, including water supply systems, irrigation, and industrial processes. Shallow-well jet pumps work well for depths up to 25 feet, while deep-well jet pumps can handle depths up to 150 feet.

- Simplicity: Jet pumps have a straightforward design with minimal moving parts, making them less prone to mechanical failure. They do not require a separate control unit or pressure tank, simplifying installation and reducing maintenance needs.

- Self-priming: Shallow-well jet pumps are self-priming, meaning they can automatically draw water into the pump without manual priming. This feature is particularly useful when the water supply is inconsistent or after periods of inactivity.

- No Submerged Parts: Unlike submersible pumps, jet pumps are installed above ground, making them more accessible for maintenance and a well pump repair when required.

- High Pressure and Efficiency: Jet pumps can generate high water pressure, making them suitable for lifting water from deep wells. Deep well jet pumps are designed to provide efficient water supply at deeper depths because of a two-pipe system utilizes pressure and suction to draw water.

- Cost-effective: Jet pumps are generally more affordable than submersible pumps due to their simpler design and construction. Additionally, their lower maintenance requirements can lead to well pump repair cost savings over time.

- Cooling: Since jet pumps operate above ground, they benefit from better cooling and are less likely to overheat during operation. A cooler pump motor can extend the pump’s life and reduce the risk of damage.

- Adaptability: Jet pumps, especially deep well jet pumps, can be adapted to function in fluctuating water level conditions. Adaptability makes jet pumps a reliable option for providing a consistent water supply, even in challenging environments.

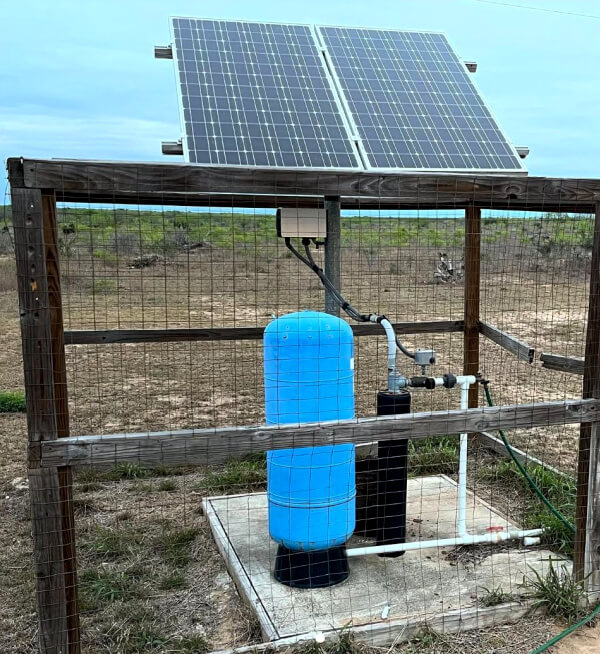

Solar Water Pumping Systems

Solar pumps offer many advantages over traditional electric or fuel-based pumps.

Some of the Key Advantages of Solar Pumps Include the Following:

- Renewable and Clean Energy: Solar pumps utilize the sun’s energy, a renewable and clean source, to power the pumping system.

- Cost-effective: The initial investment for a solar pump system might be higher than for a traditional pump. The long-term operational costs of solar pumps are typically lower. Solar pumps require little to no fuel, and maintenance costs are minimal. Over time, these savings can offset the initial investment.

- Remote Access: Solar water pumps are ideal for off-grid locations where electricity is inaccessible or limited. They provide a reliable water supply to communities or agricultural fields without expensive infrastructure.

- Low Maintenance: Solar water pumps have fewer moving parts than traditional pumps, meaning mechanical failure is less likely. This results in lower maintenance costs and higher reliability.

- Energy Storage: By incorporating batteries or other energy storage systems, solar water pumps can store excess energy generated during the day for use during periods of low sunlight or at night, ensuring continuous operation and a consistent water supply.

- Scalability: Solar water pump systems can be scaled up or down, depending on the demand. Additional solar panels or pumps can be added as needed, making it a flexible solution for varying water needs.

- Environmentally Friendly: Solar pumps reduce air and noise pollution using solar energy. This is particularly important in rural and remote areas where the preservation of natural habitats is crucial.

- Longevity: Solar panels generally have a long lifespan (20-25 years or more) with minimal

degradation in performance. As a result, a solar water pump system can provide a reliable and consistent water supply for an extended period of time.

Overall:

Solar water pumps for deep wells offer a sustainable, cost-effective, and environmentally friendly solution for well water pumping, particularly in remote or off-grid locations.

DIY Well Pump Repairs – Replacing a Submersible Well Pump Can Be Dangerous

Before attempting any DIY well pump replacement or repairs, it is important to prioritize safety.

It’s important to note that replacing a submersible water well pump can be a challenging and potentially dangerous task. Therefore, most people must be more experienced in working with well systems. Hiring a professional water well pump repair contractor is always best for replacing a submersible well pump; plenty can go wrong for most DIY property owners.

Also, it’s important to completely disinfect water well after a well pump installation. Also, check if disinfection is included when hiring a pump installer.

DIY Well Pump Safety Precautions

Here are a few safety DIY well pump repair tips:

- Disconnect all power sources to the well pump before working on it.

- Wear protective gloves and safety glasses while working.

- Do not perform repairs when the ground is wet or during wet weather conditions.

- Be cautious of moving parts within the well pump system.

Property Owners: DIY Well Pump Repairs & Maintenance

Common DIY Well Pump Repair Problems:

- Check Power Supply: Ensure the pump is connected to a working power source. Also, check that the circuit breaker or fuse hasn’t tripped. Reset or replace breakers if needed.

- Inspect the Pressure Switch: Look for any signs of wear, corrosion, or damage to the pressure switch. Replace the pressure switch if necessary, or clean the contacts and adjust the pressure settings according to the manufacturer’s specifications.

- Examine the Pressure Tank: Check the bladder tank for leaks, dents, or rust. If the tank is leaking, it may need to be replaced. Ensure the tank’s air pressure is set correctly, typically two psi below the switch’s cut-in pressure.

- Clean or Replace the Filter: Clogged filters cause well pumps to work harder. Replace your water filters if they are dirty or damaged.

- Check and Clean the Pump Impeller: The impeller is a crucial component in the pump that helps move water. Remove the pump casing to access the impeller and clean it of any debris or sediment. If the impeller is damaged, replace it with a new one.

- Inspect the Check Valve: Ensure the check valve functions correctly to prevent backflow. If it’s not closing properly or is leaking, replace the valve.

- Examine the Piping: Check the well’s piping for any visible leaks, cracks, or damage. Repair or replace the affected sections as needed.

- Troubleshoot Well Pump Motor Issues: If the motor is overheating, check for a faulty capacitor, worn bearings, or poor wiring connections. Replace or repair these components if necessary.

- Prime the Pump: If the pump has lost its prime, it won’t be able to draw water from the well. To re-prime, the pump, follow the manufacturer’s instructions, which typically involve filling a priming plug or funnel the pump’s casing with water.

- Check the Water Level in the Well: If the water level has dropped below the pump intake, the pump won’t be able to draw water. In this case, you may need to wait for the water table to rise or consider lowering the pump further into the well.

Important: Take Necessary Safety Precautions With Well Pump Repairs

Remember, while many of these maintenance and well pump repair techniques can be completed by a DIY enthusiast, it’s essential to take necessary safety precautions and consult the pump’s owner’s manual for specific instructions.

When you doubt any steps required to work on a water pumping system, it’s always best to call for a well pump service company.

When to Call a Well Pump Repair Professional

While a homeowner can perform some well pump repairs, there are certain situations when it is best to call a pump repair professional:

A water well pump professional should be called when you notice any irregularities in your water supply, such as reduced water pressure, inconsistent water flow, or murky, discolored water.

Also, experience frequent pump cycling, strange noises from the well pump, or air spurts from your faucets. These may be signs that your pump or its components are malfunctioning.

Early intervention by a professional can help diagnose and address the issue before it worsens, potentially preventing more severe damage and costly well pump repairs.

Calling a water well pump professional for regular maintenance is also important, even if no immediate problems are apparent. A well-maintained pump can ensure a reliable water supply and prolong the life of your system, reducing the future cost of repairing the water pumping system.

Most people will have their well pump & pressure systems serviced every three to five years or as the manufacturer recommends. By scheduling regular maintenance, you can prevent potential problems and ensure your water system’s ongoing safety and efficiency.

Knowing when to seek professional help can save you time, effort, and need for a potentially expensive well pump repair in the long run.

Scheduling Routine Well Pump Repair & Maintenance

Preventive maintenance is key to prolonging the life of your well pump. Many property owners schedule routine check-ups with a reputable well pump repair company at least once a year.

Water well system maintenance will help identify potential problems with your water system and fix them before they escalate, resulting in more expensive repairs or replacements.

Water Well Repair Service Agreements and Cost

Consider signing a water well repair and maintenance agreement with a local reputable well pump service provider. This provides regular maintenance visits at a reduced cost. But this does ensure your pumping system is up-to-date with well pump repairs and preventive measures as needed.

Ensure Your Family’s Safety: Well Water Testing is Affordable

The Essential Water Test Kit is perfect option for yearly water testing, certified lab testing that includes basic chemistry; heavy metals, nitrates and other inorganics; and coliform bacteria.

Annual Well Water Testing is Crucial

Testing your well water is important to ensure its safety and quality. Well water comes from underground aquifers and can be subject to contamination from various sources. Contamination may includes natural minerals, agricultural runoff, nearby industrial activities, and other land uses.

Regular water testing of your well water helps identify potential issues. It allows you to address them promptly to protect your health and the environment.

Some reasons why testing your well water is important to include:

- Health Protection: Contaminants in well water can cause short-term and long-term health issues. Especially true for vulnerable populations such as children, older adults, and those with compromised immune systems.

Several factors contribute to water pollution, such as soil degradation. Applying chemicals, fertilizers, and pesticides, pollution, and improper waste disposal near water sources can cause contamination. - Changing Conditions: Well water quality can change over time due to geological shifts, seasonal variations, and land use. Even water well construction issues can become apparent. Regular well water testing helps you with these changes and ensures your water remains safe.

- Water Well Maintenance and System Performance: Testing your well water can reveal issues with your water systems. Problems include a malfunctioning pump, surface water leaking into the well, or inadequate water disinfection or filtration. Early detection allows you to address these problems before they lead to more significant issues or costly water well repairs.

- Legal Requirements and Property Value: In some jurisdictions, well water testing may be required by law. Particularly when buying or selling a property. Moreover, having a well-maintained and regularly tested water source can positively impact your property’s value.

Regular water testing provides a history of water quality in case of a potential legal issue. - Environmental Protection: Regular well water testing can help you identify and address contamination sources, reducing potential harm.

How Often Should Well Water Be Tested?

At the very least, water wells should be tested annually for bacteria, nitrates, and any other contaminants that may be present.

Additionally, you should test your well water if you notice any changes in taste, odor, or appearance or if a flood or any other event could impact your water quality.

Consult a local water testing laboratory for guidance on testing procedures and the specific contaminants to test for in your region.

Conclusion

In conclusion, maintaining and scheduling regular well pump repair is essential to ensure a reliable water supply for your home. When faced with well pump issues, seeking the help of professional pump services is highly recommended.

Your key takeaway should be the importance of regular maintenance to extend the lifespan of your pump. Many companies offer well-maintenance programs that run your well and well pump year-round and not requiring a sudden well pump repair.

Regarding well pump repair costs, expect to pay anywhere from a few hundred dollars or much more, depending on the well pump repairs needed.

To make an informed decision, consider obtaining quotes from multiple local Well Pump Repair companies near you.

Investing in timely repairs and good water well & pump maintenance can save you from more costly issues. So, be proactive and ensure that your well-thriving water supply remains undisrupted!

Water Well Drilling and Well Repairs

Discover lasting water solutions with our expert water well drilling and reliable well repairs, tailored to meet your needs with peace of mind ensuring your home or business flows with sustainability and efficiency near you! Unlock the secret to affordable water well drilling – contact us today for a local well drilling cost estimate!

Additional Information for Water Wells & Water Quality USA and Canada

Home Drinking Water Fact Sheet

Learn About Private Water Wells

Canadian Drinking Water Guidelines

EPA Drinking Water Regulations

USDA – Install or Repair a Well

Get a monthly update of our most popular articles directly to your inbox such as Water Well Advice including Water Testing, Well Drilling... what you need to know when buying or selling Real Estate with Water Wells, Septic Systems & many other rural living topics!